Labeling is a critical aspect of the look and branding of bottled product packaging. Choosing the right label applicator ensures accurate and efficient labeling, enhancing your brand’s visibility and professionalism. However, with numerous options available, finding the best label applicator for your bottled product can be challenging. Here’s what you need to know when looking for the best label applicator to meet your specific bottle labeling requirements.

Assess Your Bottle Labeling Needs

Start by evaluating your bottle labeling needs. Consider factors such as bottle size, shape, and material. Determine if you need a wraparound label, front and back labeling, or a top or bottom label. Also, be sure to consider your needs for production speed and volume of your bottling process. Understanding your specific requirements will help you narrow your options and focus on label applicators designed to handle your bottle type and labeling preferences.

Research Bottle-Specific Label Applicators

To find the best label applicator for your bottle, explore the different types of label applicators specifically designed for bottle labeling. Some common options include wraparound labelers, front and back labelers, and vertical or horizontal orientation applicators. Research these different types, understand their features and capabilities, and determine which aligns best with your bottle labeling needs.

Consider the Label Applicator’s Adjustability and Versatility

Flexibility is crucial when selecting a label applicator for bottles. Look for applicators that offer adjustability to accommodate various bottle sizes and shapes. Ensure the applicator can handle different label materials, including paper, film, or plastic. An adaptable label applicator will allow you to meet any changing labeling requirements as your product line expands or evolves.

Evaluate Labeling Accuracy and Quality

Accurate and high-quality labeling is especially important for bottled products. Examine the label applicator’s precision and consistency in applying labels. Look for features like adjustable label sensors, alignment guides, and advanced control systems that can ensure precise label placement and minimize errors.

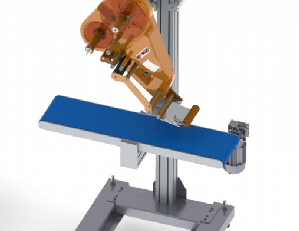

Meet the Saturno 1T Compact & 2T

Saturno 1T Compact

The Saturno 1T-Compact is a low-cost labeling line for cylindrical products for total wraparound labeling or semi-wrap-around. It includes a conveyor belt with a fixed speed of 20m / min and suspension with an engine block. The line is available with only one labeling head with a maximum label width range from 100-140-190 mm.

Saturno 2T

The Saturno 2T includes a labeling head system for front and back applications. It has a labeling line with a variable speed of 0-30 meters per minute. It is available with two labeling heads of 50, 100, 140, 190, 230, and 260 mm. Equipped with a color touchscreen display for setting the speeds and the various parameters to obtain perfect labeling.

Selecting the best label applicator for your product’s bottle is an investment in your business. Following these guidelines and conducting thorough research, you can choose a label applicator that ensures efficient, accurate, and professional labeling for your product’s bottles. Please speak to one of our sales representatives to help you decide which label applicator is right for you.