The V2000 machine is a modern and functional cartoner with a building system “with flange” which includes the following features:

- easily inspectable and cleanable; the machine is built according the GMP rules;

- format change is simple and fast, regulations with indicators, very few parts to be replaced;

- ergonomic positioning of the warehouse of cases and sheets for an easy loading;

- innovative forced opening system of the cases;

- product transport, cases and machine transmission with toothed belts to reduce sound emission and increase the reliability;

- control panel with touchscreen user interface;

- great versatility.

V2000 OPERATING PRINCIPLE:

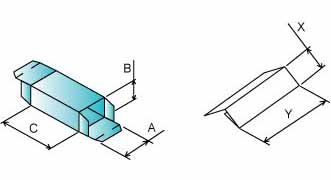

The case is picked up from the warehouse and splayed through a system of three suction cups.

The sheet is picked up from warehouse and deposited through suction cups. After which it is introduced between the conveyor belts and subsequently introduced in the vertical transport.

Products arrive to the pusher unit through a tray transport. The pusher unit insert the product and the sheet inside the case. The case is moved through a series of chain that bring them utill the exit of the machine. After the product has been introduced, the case is closed with a slot or glue.

OPTIONAL UNITS:

Automatic feeding of the product (Blister, bottle, tube, etc..).

Code reader with ejector.

Encoders: embossing or ink/embossing.

Schedule insertion device: stretched or folded.